It’s more than just artificial grass.

Turf Types

Have you ever experienced artificial turf?

Did you think about what goes into the manufacturing of synthetic turf?

It’s OK if you haven’t. Most people probably haven’t.

But, if you are wanting to learn more, here is our guide for you. Synthetic turf can be made from several materials such as nylon, polyester, or combinations of both.

Learn about the pros and cons of each kind of fiber with this comparison guide.

NYLON

Pros

- While denier and yarn composition affect durability, nylon is usually stronger in direct comparison.

Cons

- More vulnerable to expansion and contraction.

- Exposure to direct sunlight causes fading.

POLYESTER

Pros

- Not nearly as prone to expansion and contraction.

- Polyester is more UV resistant than nylon.

Cons

- Less durable pound per pound than nylon.

NYLON & POLYESTER

Pros

- Water-resistant properties.

- Resistance to tearing.

- Less susceptible to saltwater corrosion and mildew.

Cons

- Nylon and Polyester are flammable. However, each responds differently to fire; nylon melts before it burns, polyester melts before it burns.

It’s Not Only About Fiber

There are lots of artificial grass manufacturers out there pitching their products. But, we’d like to let you in on a little secret. One of the most important elements of synthetic grass is not only the material the fiber (grass blades) is composed of. Turf is a system that needs to be installed correctly for ideal performance. The following are just a few components that establish a high-quality turf from a low-quality turf.

BACKING

The backing is composed of two layers and coated with urethane to finish. These items are vital because they secure the fibers (grass blades) in place, allow water drainage, and stand up to abrasion from the base material.

INFILL

Infill is a crucial component. It adds labor and time but is the final touch that makes sure your warranty is good and your project performs well. Infill adds ballast, this ensures the turf is free from wrinkles and dimensionally stable. It provides additional protection to the yarn and backing, aides drainage, and ensures a proper footing.

YARN FIBER

The yarn fiber is comprised of resins designed to solve the twin challenges of softness and durability. Fibers can be had in many shades and combinations that allow your eye to see many greens. In addition, thatch is often added for realism.

Keeping Things Cool with Science

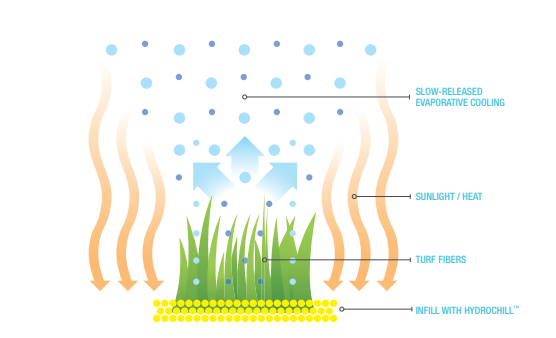

One particular product we love is HydroChill™, our patented evaporative cooling technology.

Perspiring is a natural form of thermoregulation known as evaporative cooling. Evaporation of moisture from the surface of the skin yields a cooling effect. Likewise, HydroChill™ has demonstrated the ability to cool synthetic turf surfaces by using the same principle of evaporative cooling. As the surface of the turf is heated by the sun’s radiation, moisture in the HydroChill™ turf is released. Evaporating moisture removes heat, leaving a cooler, more comfortable surface for the players.

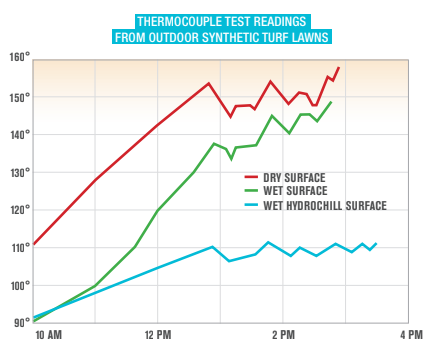

Astandard wet lawn will generate some cooling, but temperatures often rise quickly and can exceed uncomfortable levels of heat. A HydroChill™ lawn has demonstrated the ability to create a notable temperature differential in real-world applications. HydroChill™ has achieved 30° to 50° lower surface temperatures, based on actual lab and outdoor thermocouple testing, versus a typical synthetic turf system.

Less Work. More Play.

Southwest Greens isn’t just a product, it’s also a solution. A solution that utilizes substantially less water each year, substantially reduces the impact on mother nature, and requires much less maintenance. All of which gives you the option of less work, more play.